Description

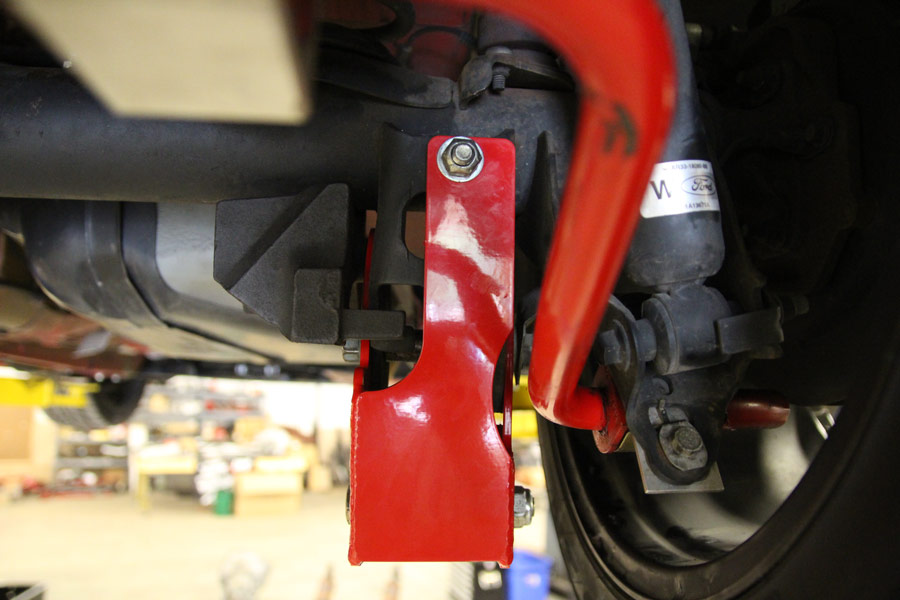

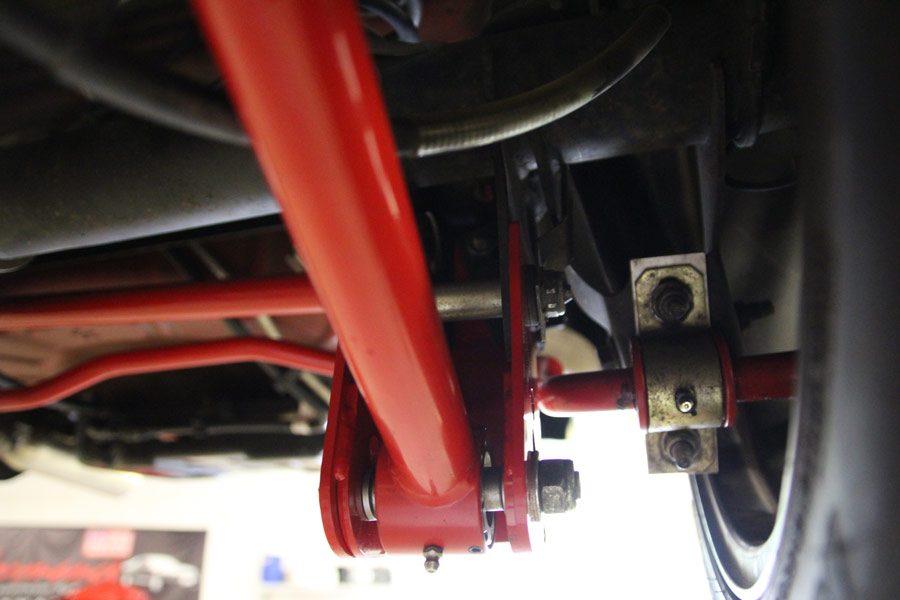

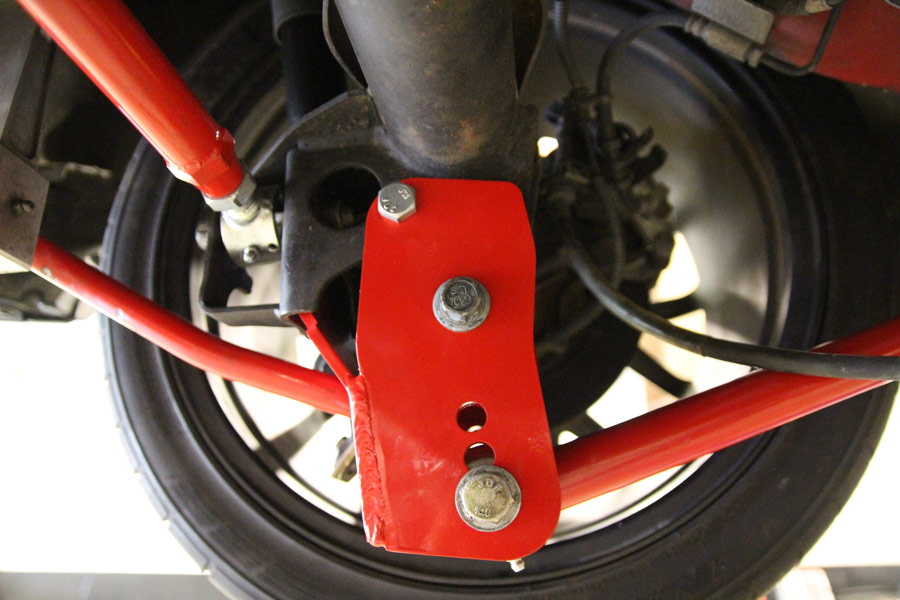

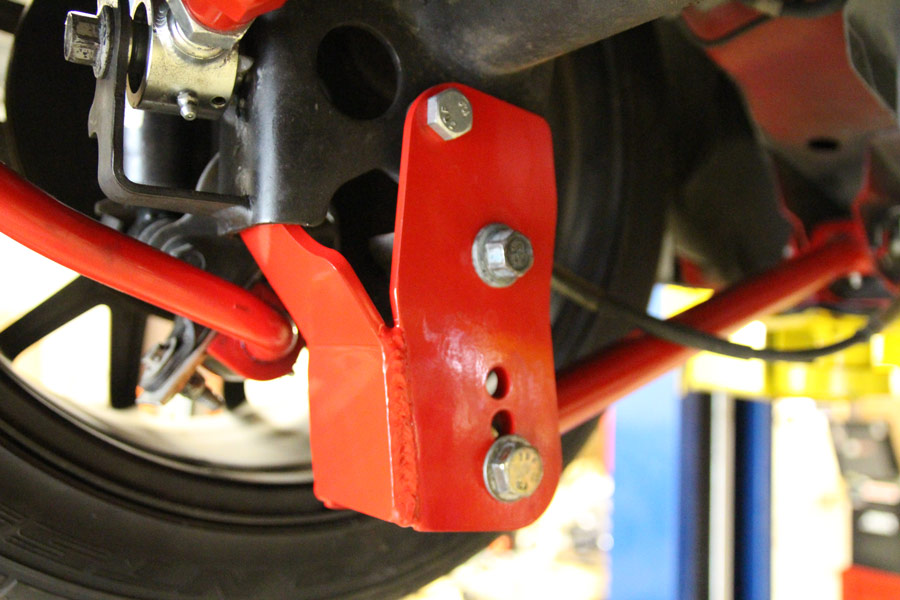

UMI is proud to announce an improvement to our tried and true P/N 1060 lower control arm relocation brackets for the Ford Mustang. With the increasing popularity of 700+ HP cars and corresponding reduction in 60 ft times, we’ve taken the proactive approach and increased material thickness to ¼” in critical locations. We’ve also added a third adjustment hole and improved the contours in a few key locations. Lower control arm relocation brackets improve forward traction and help tires plant the tires upon launch. Road race and auto-x competitors can use the upper holes to tune roll steer or simply correct lower trailing arm angles on lowered cars.

Wheel hop or traction issues? We have the solution! Optimize your vehicle’s instant center and improve forward traction by lowering the rear of the lower control arm 2″, 2-3/4″, or 3-1/4″. These bolt-in brackets are CAD designed to accommodate factory lower control arms as well as all popular aftermarket styles. Robust flanges inside the brackets add reinforcement and ensure factory bushings bolt right in. Brackets installed can provide an average 0.10 second (or better) 60-foot reduction and an overall improvement in launch consistency. Brackets are constructed of a combination of 3/16” and ¼” thick mild steel brackets for increased strength, CNC laser cutting ensures precision tolerances every time. Relocation brackets are designed to work on both lowered and non-lowered vehicles and feature multiple settings to optimize vehicle handling and traction.

Installation: UMI P/N 1060 are 100% bolt on itemand require no welding, drilling or cutting. All necessary hardware is included for this simple bolt on application. Kit is supplied with hardware, installation instructions.

Features:

- Works with factory height or lowered vehicles. Simply bolt-in & launch using your existing factory control arms.

- Multiple adjustment holes ideal to correct control arm angle on lowered vehicles while improving traction.

- Choose 2″, 2-3/4″, or 3-1/4″ drop to optimize vehicle handling and traction.

- Track testing shows an average of 0.10 second reduction in 60-foot times.

- CAD designed, CNC laser cut 3/16″ and ¼” mild steel.

- Adjustment holes follow natural arc of lower control arm for direct bolt-in.

- New grade 10.9 hardware included.

- Manufactured with pride in Philipsburg, PA – USA.

A-ARMS

A-ARMS

CHASSIS REINFORCEMENT

CHASSIS REINFORCEMENT

SPRINGS & SPRING SPACERS

SPRINGS & SPRING SPACERS

SPRING & SHOCK KITS

SPRING & SHOCK KITS

LEAF SPRINGS

LEAF SPRINGS

SHOCKS & SPRINGS

SHOCKS & SPRINGS

STEERING

STEERING

TUNNEL BRACE

TUNNEL BRACE

SPRINGS

SPRINGS

ADJUSTERS

ADJUSTERS