G-Body Suspension Install

The folks over at Car Craft hav been building a G-Body, dubbed MalibuST. This wagon is set to handle twists and turns and they knew they needed the best suspension to make that happen. We set them up with a complete Stage 3.5 kit that will turn this car from a slouch to a track superstar in no time while still having street manners. Read along below for the full installation!

Car Craft Article By Jesse Kiser

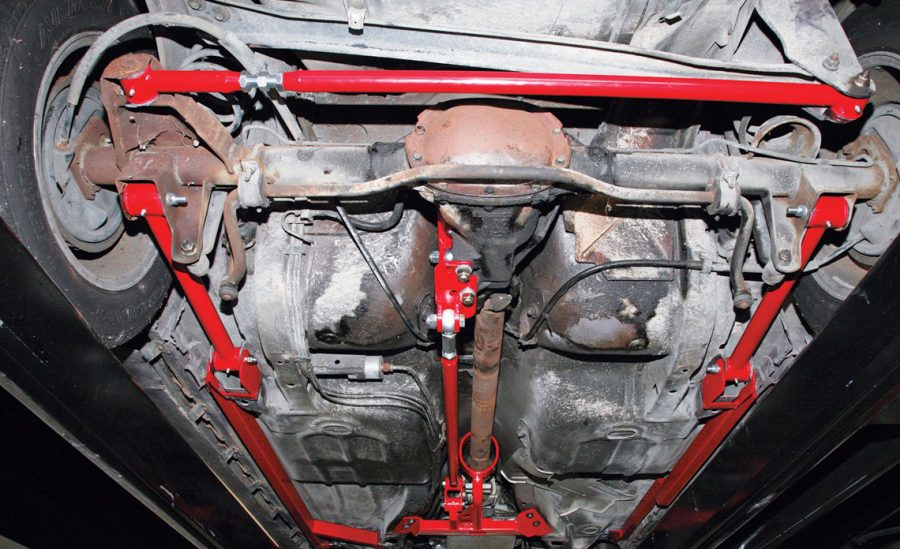

The true heart and soul of MalibuST (pronounced Mali-boost) is the wagon’s ability to set-up and dominate a corner like a Miata, but with a lot of extra leg room. Being able to muster a mid-sized GM wagon through a corner takes a lot more engineering than worn-out and rusty stamped-steel control arms with 30-year-old ball joints. This month we upgrade the Malibu’s front suspension and stopping power with a UMI G-body Stage 3.5 handling kit and Wilwood Superlite 6R brakes.

We concluded our last installment with the wagon missing its entire front clip. This gave us the room to paint the frame rails and firewall using our Summit Racing Paint Prep Combo and Eastwood 2k spray paint, leaving us a blank canvas for this month’s tasks.

UMI Performance offers a total of seven kits, including half-steps for the G-Body. Kits begin with the Stage 1 system ($1,149 retail) and work up to the more aggressive Stage 4 ($3,699.99) or Corner Max kit ($2,419.99). Stage 1 includes shocks and lowering springs and if you want the maximum performance, Stage 4 features double-adjustable Viking shocks and tubular control arms. “First, we ask the customer, ‘what are you doing with the car 80 percent of the time?” said Performance Engineer Ramey Womer.

For us, we plan to street drive the car to autocross and road racing events, making the Stage 3.5 kit with 2-inch lowering springs the right temperature porridge for our project. The kit includes tubular a-arms with upgraded Delrin bushings, 1 1/4-inch sway bar, rear control arms with roto-joints, adjustable rear upper arms, and all the necessary hardware. What makes the kit a 3.5 over a Stage 3 is the adjustable chassis-mounted rear sway bar and UMI rebound-adjustable monotube shocks.

Installation Begins

Our G-body has a lot of suspension woes like improper geometry, 40 years of abuse, and soft and non-adjustable suspension settings. The UMI Performance kit solves all that. First, tubular a-arms reduce any a-arm flex you’d find in the stamped-steel factory arms. Second, the springs are much stiffer and the shocks are rebound adjustable. Finally, the new suspension layout corrects the terrible geometry with a new camber curve—which is the wheel’s camber angle throughout wheel travel in any given corner.

“Everything we do—loaded, unloaded, turning, not turning—we’re trying to manipulate the contact patch of the tire on the road,” said Ramey. “Consider a car with proper camber curve like a Corvette.” A Corvette’s outer wheel during a turn will tuck up into the wheel well, keeping the tire planted and the body from rolling over. The G-Body taking the same turn will begin by rolling up onto the sidewall of the tire as the camber curve starts off in the wrong direction. The suspension then tips over its center point and into the correct camber, with the wheel going up into the wheel well. It will get to a preferable camber angle eventually, “but by that point, the car is already out of whack,” said Ramey, and good camber after you blow your apex is pointless.

The Corvette attains this correct camber curve due to the angle of the upper a-arms, which are sloped upward as they point towards the wheel. The G-body’s original upper a-arms are angled downward as they point towards the wheel, meaning they have to travel outward and level off, before sucking the wheel up into the wheel well.

Geometry Changing

UMI’s new tubular a-arms and longer upper ball joints help achieve this new curve. This ball-joint length adds 1/2-inch to the stock spindle height but doesn’t change the ride height or travel (the length of the lower ball joint affects ride height). Instead, it points the a-arm in the right direction, before you even hit the first corner. The more aggressive Corner Max kit offers an even longer .9-inch ball joint for about $50 more. “You may not notice driving it every day, but if you autocross it every weekend you’ll likely feel more front-end grip [with the taller ball joint],” said Ramey. “The half-inch ball-joint is a moderate improvement, for a moderate cost”

We need to stop after slaying those corners, so we enlisted the help of Wilwood brakes. The Forged Narrow Superlite 6R big-brake kit features an intense braking package with 13-inch Spec-37 iron SRP rotors, to which we added the black Electro Coating and drilled and slotted rotors. With mostly street use planned for the car, we don’t expect excessive pad wear from the chosen rotors, which will cut down on pad glazing and keep the brakes cool during aggressive auto-crossing. This kit is ideal for non-ABS American cars doing double duty as street and track machines and perfect for stopping our heavy wagon.

In a future installment, we’ll finish building and plumbing our complete braking system and suspension when we build a quick and easy Ford 9-inch. Then we’ll be ready to hit the track.

A-ARMS

A-ARMS

CHASSIS REINFORCEMENT

CHASSIS REINFORCEMENT

SPRINGS & SPRING SPACERS

SPRINGS & SPRING SPACERS

SPRING & SHOCK KITS

SPRING & SHOCK KITS

LEAF SPRINGS

LEAF SPRINGS

SHOCKS & SPRINGS

SHOCKS & SPRINGS

STEERING

STEERING

TUNNEL BRACE

TUNNEL BRACE

SPRINGS

SPRINGS

ADJUSTERS

ADJUSTERS